Testing & Tagging in Rockhampton

Ensuring the Safety of Your Electrical Appliances

Maintain Safety Standards

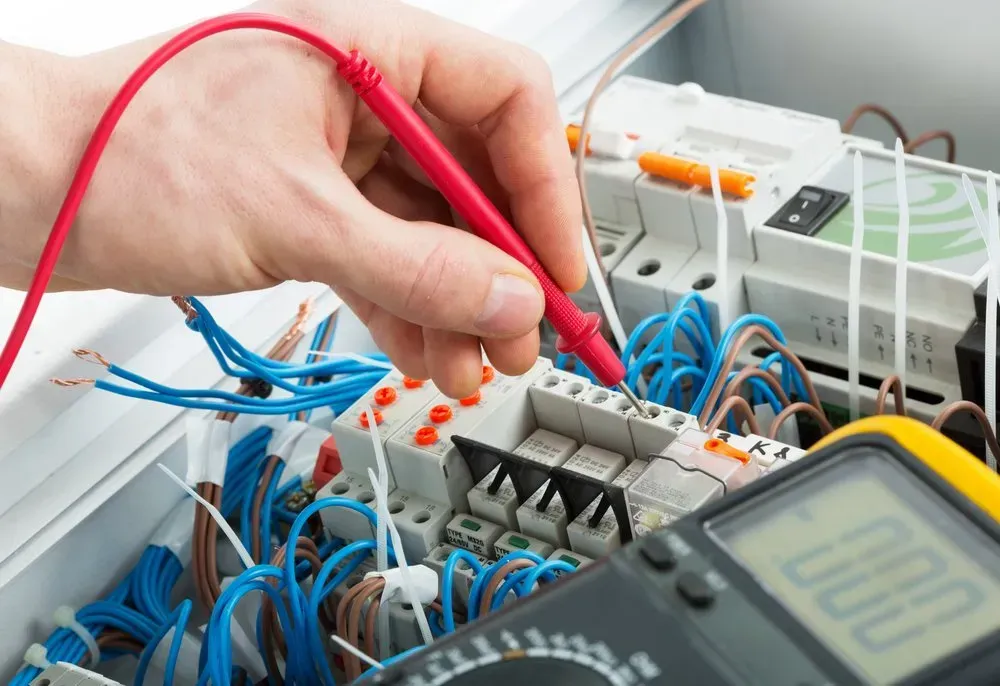

To remain compliant with Safe Work Australia guidelines, arranging regular testing and tagging for electrical equipment is essential. Hazlec Services provides testing and tagging services across Rockhampton, Yeppoon, Gracemere and surrounding areas. Our team inspects machines, equipment and electrical appliances to help identify potential issues early. All work is completed by fully licensed and insured electricians who focus on accuracy and safety.

- Testing and tagging for electrical equipment, machinery and appliances

- Early identification of faults to help reduce safety risks and downtime

Regular testing and tagging can help prevent minor electrical issues from developing into costly or dangerous problems. Our electricians use up-to-date diagnostic tools and follow current safety requirements to deliver thorough inspections and reliable results.

Contact Hazlec Services today on 0419 302 314 to arrange testing and tagging services. Smoke alarm installations and switchboard upgrades are also available.

Why Test & Tag?

Here are just a few reasons why testing and tagging is important for any business:

- Helps maintain workplace safety standards

- Allows faults to be identified early before they develop into larger issues

- Reduces the risk of fines for non-compliance

- May help lower insurance risk and premiums

- Supports efficient maintenance and equipment management

If you would like to arrange a test and tag service, get in touch today to enjoy greater peace of mind.

Clear Communication

Prompt Service

Quality Workmanship

Get A Quote

Have a question or need a quote? Fill out the contact form and our team will be in touch.

Contact Us

Thank you for contacting Hazlec Services Pty Ltd.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

FAQ

Which types of equipment usually require testing and tagging?

Common items include power tools, extension leads, office equipment and portable appliances. Equipment that is moved regularly or used in higher risk environments often requires more frequent testing. The type of workplace can influence testing requirements. Regular checks help reduce electrical hazards.

How often should testing and tagging be carried out?

Testing frequency depends on the environment and how equipment is used. Construction sites and workshops often require more frequent testing than offices. Industry guidelines outline recommended intervals. Following these intervals helps maintain safety and compliance.

What happens if faulty equipment is identified during testing?

Faulty equipment is typically removed from use to prevent risk. Repairs or replacements may be required before the item can be safely used again. Identifying issues early helps avoid more serious faults. This process reduces the likelihood of accidents or downtime.